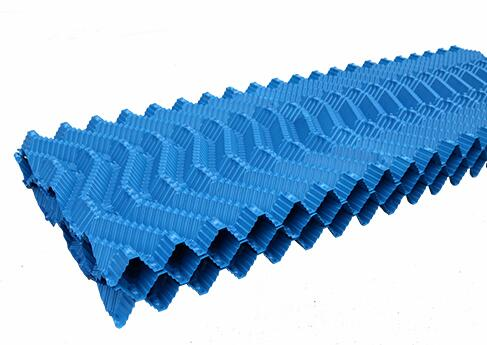

What are the Benefits of Using FRP?

FPR materials are indispensable for building construction. What are the specific benefits of using it? Read on for more information.

1. Weight

Going hand-in-hand with a quicker setup time is FRP's weight. FRP is known for being light-weight. As a matter of fact, it has to do with eight times lighter than enhanced concrete-- indicating FRP is likewise less labor-intensive to use and also mount, and also requires less tools. This material likewise calls for less labor during removal processes. See below to compare the total weight of FRP to the overall weight of precast concrete.

As you can see from the graph, FRP is considerably lighter than precast concrete, with an FRP panel weighing regarding 5,000 pound and a precast concrete panel weighing almost 41,000 lb. Using a lighter material makes it easier on your workers, saves money on labor prices, as well as places much less stress on the framework. The lower the weight of the material being utilized, the much less wear and tear the facilities will certainly experience all at once.

2. Production and Installment Time

When developing the design for your general facilities strategy, it is very important to consider the amount of time that will certainly be required not just for the whole job, however likewise for each and every step within the process. Obviously, saved time translates to saved costs, but you certainly do not wish to give up high quality for effectiveness. FRP can provide an ideal balance, helping to conserve useful manufacturing time while still giving the needed quality, strength, and sturdiness. Listed below, compare the manufacturing as well as installment time of FRP to that of precast concrete:

As you can see from the graph, FRP's overall manufacturing time is 15 days less than that of precast concrete. This converts to more than 2 weeks' worth of conserved labor costs and also total downtime for facilities advancement. FRP additionally requires much less complete installation time than precast concrete-- nearly five days less, generally.

Thanks to this much shorter installment time, engineers using FRP don't need to complete their job exclusively throughout the workweek. Rather, they can opt to do installment work with the weekends, as well, when there is less traffic jam and also end users will experience less inconvenience as well as less disruptions to their commutes.

Suggested reading:

Construction & Real Estate

3. Repair

What is the difference between rubber and foam rubber?

Laminated Bridge Bearings: Enhancing Safety and Structural Performance

An Overview of Agricultural Water Storage Tanks

Galvanized Corrugated Steel Plate: Features and Applications

Advantages of Hot-Dip Galvanized W-Beam Guardrails

Why You Need a Corrugated Steel Pipe?

FRP frameworks are very trusted and also low-maintenance, but they should not be thought about maintenance-free-- fixings calling for area solution will certainly require to be done on rare events. Executing yearly regular examinations (at minimum) will assist guarantee prospective issues can be caught before they become an issue. If a concern has been recognized and reported (ex. fractures, crazing, staining, too much wear, etc), a field solution technician will be sent to complete the repair work.

As mentioned, frameworks made from steel, concrete as well as wood are prone to routine repair work, along with those made with brick and also tile-- that's also where FRP can be found in. Fiberglass can be made use of for patch fixings on bridge outdoor decking as well as linings can be put on culverts, pumps, tank and also pipes to shield less-resistant products from future damages. FRP can also be utilized for wrapping bridge piers and also columns.

Repair work made with FRP add up to long-term cost financial savings. Because the product is corrosion-resistant and has a lot longer life span, it's a wonderful alternative to make use of when fixing as well as shielding existing frameworks. Take a look at our brief case research for more information concerning exactly how FRP repairs decrease prices.

4. Rust and Maintenance

Offering high toughness as well as strength, in addition to dependable resistance to deterioration, FRP is resilient and minimizes the need for ongoing maintenance. The lack of constant maintenance and repairs aids to reduce costly labor as well as product expenses and likewise stops trouble to end users, given that repair service downtime is reduced.

And, given that FRP is durable and immune to corrosion, the long-lasting expenses end up being much less as well.

Though FRP does have a slightly higher price point per square foot at initial setup, the material permits several advantages in regards to long-term cost savings. Since FRP causes less stress on the framework as well as is much more resilient than various other products, it decreases the demand for costly fixings or reconstruction in the future. For example, bridges as well as platforms constructed from products such as strengthened concrete, steel, or timber often break down 15 to two decades after preliminary installation-- needing incredibly pricey repair work or even an entire brand-new investment to rebuild from the ground up. FRP, nonetheless, is built to last as well as will not experience deterioration in time like several other construction products.

We are an FRP pipe manufacturer, please feel free to contact us if you need them.

Advantages of HDPE Ground Protection Mats

Pool Mosaics: Transforming Your Swimming Pool into a Work of Art

The Essential Guide to Welded Pipe Caps: Uses, Installation, and Benefits

Applications and Benefits of PUR Hot Melt Adhesive

Hydraulic lifting dam and its characteristics

Advantages of Choosing Granite Headstones for Lasting Memorialization

What Are the Benefits of Building a Shipping Container House for Sustainable and Affordable Living?