What is The Purpose of Fill in a Cooling Tower?

Cooling towers are an integral component of many industrial and commercial facilities. They serve the important purpose of removing excess heat from industrial processes or air conditioning systems. In order to achieve this, cooling towers rely on a process of evaporation and heat transfer. However, in order for cooling towers to function properly, they require fill. In this article, we will explore the purpose of filling in a cooling tower.

What is fill in a cooling tower?

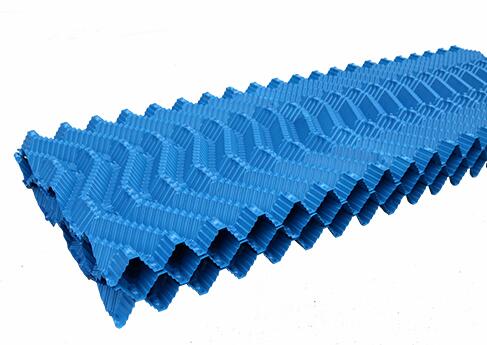

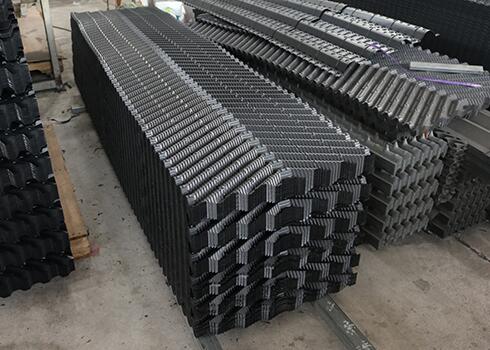

Fill refers to the material that is used to fill the space inside a cooling tower. The fill is a critical component of the tower because it provides a large surface area for water to flow over, which facilitates the transfer of heat from the water to the air. Fill is typically made of PVC or another plastic material, and it is designed to be lightweight and durable.

The purpose of filling in a cooling tower

The primary purpose of filling in a cooling tower is to increase the surface area of the water that is exposed to the air. As water flows over the fill material, it spreads out into a thin film, which allows for maximum contact with the air. This increased surface area maximizes the amount of heat that can be transferred from the water to the air.

The fill material also creates a large amount of turbulence in the water as it flows through the tower. This turbulence helps to break up any stagnant areas within the water and ensures that all parts of the water are exposed to the air. This, in turn, improves the overall efficiency of the cooling tower.

Another important purpose of filling in a cooling tower is to minimize the amount of water that is lost through evaporation. When water is sprayed onto the fill material, it is broken up into droplets, which helps to minimize the amount of water that is lost through evaporation. This is important because evaporation can be a major source of water loss in a cooling tower, and minimizing this loss can help to reduce operating costs.

Types of fill

There are two main types of fill that are commonly used in cooling towers: film fill and splash fill. A film fill is a type of fill that is designed to create a thin film of water over the surface of the fill material. This film allows for maximum contact between the water and the air, which maximizes the efficiency of the cooling tower. Splash fill, on the other hand, is designed to break up the water into small droplets as it flows over the fill material. This creates a large amount of turbulence within the water and ensures that all parts of the water are exposed to the air.

Conclusion

In conclusion, fill is a critical component of a cooling tower. Its primary purpose is to increase the surface area of the water that is exposed to the air, which maximizes the amount of heat that can be transferred from the water to the air. The fill material also helps to create turbulence within the water, which ensures that all parts of the water are exposed to the air. Additionally, the fill material helps to minimize water loss through evaporation, which can help to reduce operating costs. By understanding the importance of filling in a cooling tower, facility managers can ensure that their cooling towers are operating at peak efficiency and are providing the necessary cooling for their processes or air conditioning systems. We are a cooling tower fill supplier. If you are interested in our products, please contact us now!