Explore Long Reach Excavators - For Sale, & Attachments

Explore Long Reach Excavators - For Sale, & Attachments

What are long-reach excavators, and what are they used for?

Long-reach excavators, also known as long boom or long-arm excavators, are specialized excavators equipped with extended-reach attachments. These attachments feature elongated booms and arms, allowing the excavator to reach greater depths or heights than standard excavators. Long-reach excavators are commonly used for tasks such as dredging, deep excavation, slope work, and reaching over obstacles like buildings or rivers.

Want more information on 20 meters long reach arm price? Feel free to contact us.

What are the benefits of using a long-reach excavator?

The primary benefit of using a long-reach excavator is its extended reach, enabling operators to access areas that are otherwise challenging to reach with standard excavators. Long-reach excavators are particularly useful for projects that require working in deep trenches, reaching across obstacles, or excavating below ground level. Additionally, long-reach excavators can increase productivity by reducing the need for manual labor and minimizing the time required to complete tasks.

How do I choose the right long-reach excavator for my project?

Choosing the right long-reach excavator depends on factors such as the depth or height of the excavation, the reach required, and the specific conditions of the work site. For general excavation tasks, a standard long-reach excavator may suffice. At the same time, specialized configurations may be needed for projects such as dredging or reaching over obstacles. Our team of experts can assess your project requirements and recommend the most suitable long-reach excavator configuration to meet your needs and maximize efficiency.

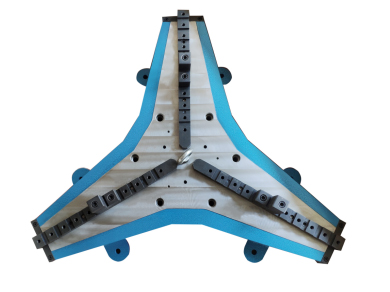

What types of attachments are available for long-reach excavators?

Long-reach excavators can be equipped with various attachments to suit different applications. Common attachments include buckets, hydraulic breakers, grapples, thumbs, and augers. These attachments are designed to enhance the versatility and functionality of the long-reach excavator, allowing operators to perform a wide range of tasks with precision and efficiency.

Can long-reach excavators be rented or purchased?

Long-reach excavators can be rented or purchased depending on the duration and frequency of use and budget considerations. Renting a long-reach excavator is a cost-effective option for short-term projects or occasional use, while purchasing may be more economical for long-term or frequent use. Our team can provide guidance on the best option for your specific requirements and help you select the right long-reach excavator for your project.

What maintenance is required for long-reach excavators and attachments?

Regular maintenance is essential for keeping long-reach excavators and attachments in optimal condition for efficient operation. Inspect the equipment before each use for signs of wear, damage, or hydraulic leaks, and address any issues promptly to prevent further damage or safety hazards. Lubricate grease fittings, hydraulic hoses, and pivot points according to the manufacturer's recommendations. Proper storage in a clean, dry environment when not in use can also help prevent corrosion and deterioration.

Excavators Purchasing Guide

Table of Contents

- Introduction

- Trends

- Types

- Specs

- Attachments

- Choosing a Dealer

Introduction

Today, excavators are state-of-the art, using hydraulic power with smaller turning radiuses for tight spaces and intuitive joystick commands. Industries such as construction, utility, public works, mining, demolition, forestry, and landscaping use them every day to dig the trenches, holes and foundations.

The components of an excavator include:

[table]

Component, Description

Cab, This is where the operator sits and controls the machine through pedals and joysticks.

House, "The house contains the engine, oil and fuel cylinders. It is connected to the undercarriage with a cylindrical casket to enable 360 degree rotation."

Engine, The engine (typically diesel because of the amount of power needed) sits in the house and powers not only movement of the machine but also the hydraulics used to move the boom and attachments.

Undercarriage, The undercarriage has the gears and motor that facilitates movement of the machine over the ground.

Boom, This is the extension that connects to the bucket and other attachments.

Stick, "The stick connects the boom and the undercarriage, extending or retracting depended on the distance necessary to operate the boom and dig"

[/table]

Choosing the right excavator depends on many factors. Size, controls, and jobsite locations rank high on the list of things to consider.

If you want to learn more, please visit our website 20 meters long reach arm for sale.

Additional reading:Unlocking the Door: Key Questions to Ask When Ordering Used Metal Pipe

How to Install Corrugated Drain Pipe: A Step-by-Step Guide

How to Choose the Best Hel-Cor Galvanized Corrugated Steel Pipe for Your Project?

How to Choose the Best Corrugated Metal Culvert Pipe for Your Budget?

10 Questions You Should Know About Rainwater Harvesting

Culvert Pipes for Sale: Plastic vs. Metal – Which Reigns Supreme?

Cereal Bar Forming Machines for Unrivaled Benefits

Size

The size of an excavator will determine your digging depth and dig power. The industry refers to excavators in different size classes:

[table]

Operating Size, Terminology

0 - 6 Metric Tons, "Micro, Compact"

6 - 25 Metric Tons, "Mini, Construction Class"

25 - 40 Metric Tons, "Mini, Construction Class"

40 - 90 Metric Tons, "Large, Production Class"

[/table]

You want to purchase an excavator that will meet your job requirements ' and nothing more. If you purchase one that provides a deeper depth and stronger power than you really need, you could be wasting money on extra costs for fuel and possibly transport in addition to the extra expenditure on the machine itself. Really think about the size that makes the most sense for your company now and the foreseeable future.

Controls

There are two main types of excavator controls. One is specified by the Society of Automotive Engineers (SAE), and the other is by the International Organization for Standardization (ISO).

The two controls are very similar with the biggest difference being that the controls for the boom arm and dipper arm are reversed. SAE controls are the preferred method in the U.S. It's important to know the difference, especially if you are considering buying a used excavator.

Jobsite locations

Where you are going to use the machine is a critical consideration. Tight spaces require smaller machines, for instance; however, you want to look into a machine that is small but still provides the power you need.

In addition, evaluate how deep you dig and the type of breakout force you will need to get through different materials. Differences in soil types can dictate what power you need, how deep you will go and what accessories you need to break through, remove or cultivate the finished product.

Cost

When it comes to excavators, one of the decisions you'll have to make is used or new. Depending on what you choose, the prices will vary. Prices range from $100,000 for a mini-excavator to $500,000 for a large excavator.

You also have the option to rent an excavator on a job-by-job basis. If you are not going to use the excavator for every job, renting as needed may be the most cost-efficient option. Most rental companies even offer delivery as well. You can rent an excavator for $2,000 to $10,000 a month, depending on the size and type of excavator.

Leasing an excavator allows you to get the type of excavator you need for a job, at a more affordable price and for a longer period of time. While rental prices are higher for the same time period, leasing holds you responsible for maintenance and transportation costs.

This purchasing guide will discuss the trends, types, and excavator specifications that will help you choose the best excavator for your job. It will also provide information about various attachments available and suggest questions you should ask when interviewing dealers.

Contact us to discuss your requirements of high reach arm demolition price. Our experienced sales team can help you identify the options that best suit your needs.

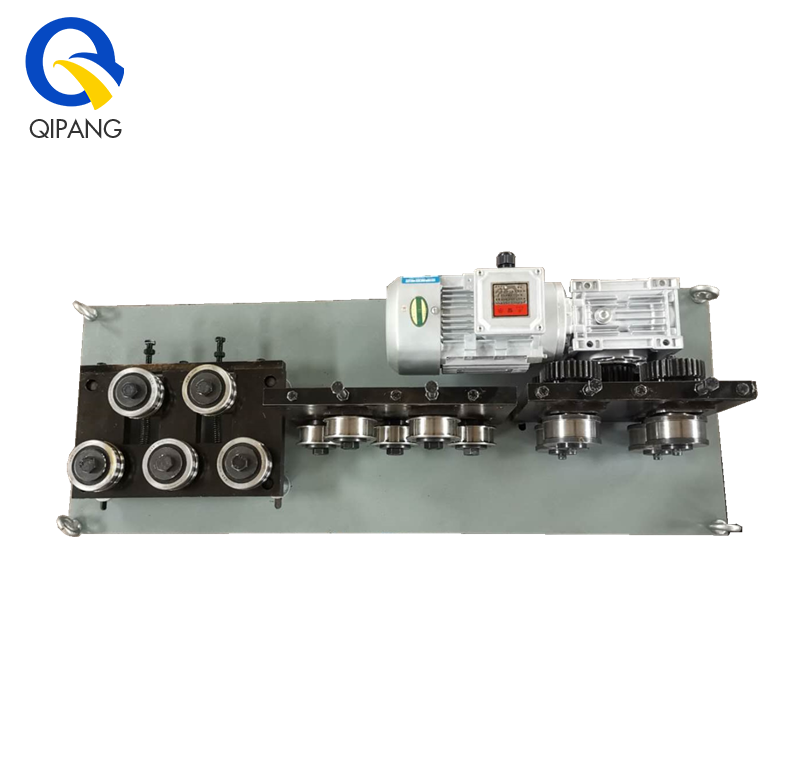

What is the working principle of tube mill?

What are the cons of lost foam casting?

Comparing Vertical Rolling Machines vs Horizontal Rolling Machines

Exploring Different Maize Flour Milling Machine Types and Their Applications

Questions about CNC Metal Spinning Machines

What is a slip ring motor used for?

What is PCB Labeling Machine