What are the Types of Electrical Flexible Conduits?

Electrical flexible conduits are essential components used to protect and route electrical wires and cables in various applications. They offer flexibility and ease of installation, making them ideal for both residential and industrial settings. However, with numerous types and materials available, choosing the right electrical flexible conduit can be a daunting task. This guide will help you navigate the selection process and make an informed decision based on your specific requirements.

Understand Your Application

The first step in choosing the right electrical flexible conduit is to understand the specific needs of your application. Consider the following factors:

A. Environment and Location

Assess the environment in which the electrical conduit will be installed. Is it indoors or outdoors? Will it be exposed to extreme temperatures, moisture, or chemicals? Different conduits are designed to withstand varying environmental conditions.

B. Flexibility and Bending Radius

Determine the level of flexibility required for your application. Some projects may involve tight bends, so selecting a conduit with a smaller bending radius will be crucial.

C. Mechanical Protection

Consider the level of mechanical protection needed for the wires or cables passing through the conduit. For rugged environments or areas with potential physical hazards, choose a conduit with higher impact resistance.

D. Electrical Requirements

Ensure the conduit you choose complies with electrical codes and standards for your specific application. It should provide proper grounding and protection against electrical interference.

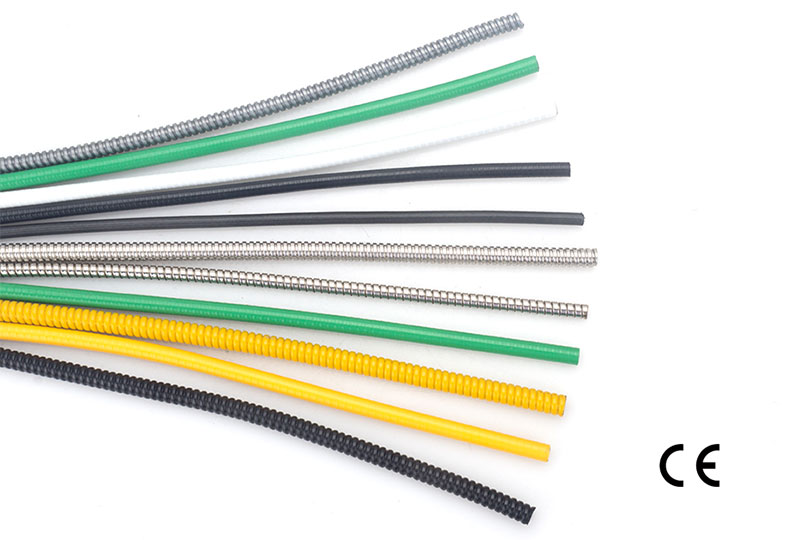

Types of Electrical Flexible Conduits

There are several types of electrical flexible conduits available, each with unique characteristics suitable for different applications:

A. Metallic Conduits:

Galvanized Steel Conduit: Offers excellent mechanical protection and is ideal for industrial applications where durability is essential.

Stainless Steel Conduit: Resistant to corrosion, making it suitable for harsh environments and outdoor applications.

Aluminum Conduit: Lightweight and corrosion-resistant, often used in aerospace and marine applications.

B. Non-Metallic Conduits:

PVC Conduit: Cost-effective and easy to install, suitable for most residential and light commercial applications.

Nylon Conduit: Known for its high flexibility and resistance to oil, making it suitable for machinery and equipment.

Liquid-Tight Flexible Conduit: Designed to resist moisture and oil, commonly used in outdoor and wet environments.

Different types of conduits, such as metallic and non-metallic, offer unique characteristics suitable for various applications. Ensure the conduit size is appropriate for accommodating the wires or cables, and check for compliance with relevant standards. By carefully evaluating these factors, you can confidently select the perfect electrical flexible conduit for your needs, ensuring a safe and efficient electrical system.