The Science Behind Tri-cone Drilling Bits: How Do They Conquer the Earth's Depths?

In the world of mining and oil exploration, the quest to reach greater depths and extract valuable resources demands cutting-edge technology and innovation. At the heart of these operations lie Tri-cone Drilling Bits, remarkable pieces of engineering designed to penetrate the Earth's depths.

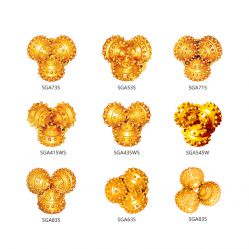

The Anatomy of a Tri-cone Drilling Bit

A Tri-cone Drilling Bit is a complex assembly consisting of three rotating cones, each studded with teeth or cutting elements. These cutting elements are strategically arranged to facilitate the drilling process. Let's delve into the science behind their functioning.

1. Cutting Structure

The teeth or cutting elements on the cones are typically made from extremely hard materials like tungsten carbide. These materials are chosen for their exceptional hardness and wear resistance. As the bit rotates and applies downward force, these cutting elements engage with the rock formations, gradually chipping away at them.

2. Weight on Bit (WOB)

The Weight on Bit is the force exerted by the drill string and rig's weight onto the drill bit. It is a critical factor in the drilling process, as it determines the effectiveness of the cutting elements. The greater the WOB, the more efficiently the bit can break and remove rock.

3. Rotational Speed

Rotational speed plays a crucial role in drilling efficiency. The cones rotate at different speeds, creating a "shearing effect" as they engage with the rock. This shearing action helps reduce the rock to cuttings that can be easily removed from the borehole.

4. Hydraulic Circulation

As the drilling progresses, drilling fluid or mud is pumped through the drill string and out of nozzles on the bit. This serves multiple purposes: cooling the cutting elements, carrying away cuttings, and providing hydraulic force to clean the bit's teeth. Proper mud properties and circulation are vital for bit performance.

5. Bearing Systems

Bearing systems within the cones are essential for maintaining the integrity of the rotating cones. These bearings are designed to withstand the axial and radial loads encountered during drilling.

6. Formation Analysis

Before drilling commences, geologists and drilling engineers analyze the geological formations to determine the best bit type and design. The science of formation analysis helps ensure that the right Tri-cone bit is selected for the specific geological conditions.

Tri-cone Bits in Action

Tri-cone Drilling Bits are highly versatile and can be customized for various drilling applications, including oil exploration, mining, water well drilling, and geothermal drilling. They are especially effective in drilling through hard and abrasive rock formations.

Tri-cone Drilling Bits exemplify the synergy between engineering, material science, and geology. Their ability to conquer the Earth's depths with precision and efficiency is a testament to human ingenuity. As technology advances, these remarkable tools continue to evolve, enabling us to explore and extract resources from increasingly challenging environments. In the ever-expanding world of resource extraction, Tri-cone Drilling Bits are at the forefront, drilling deeper and uncovering the Earth's treasures.