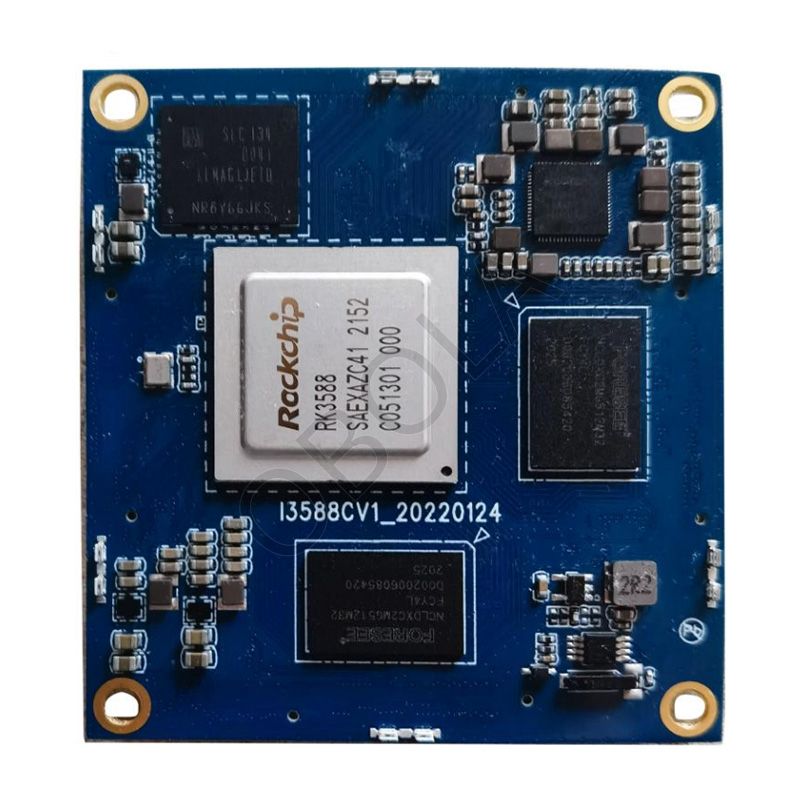

Mastering Multilayer PCB Design: Essential Guidelines For Success

With competitive price and timely delivery, CHANYEE sincerely hope to be your supplier and partner.

### Mastering Multilayer PCB Design: Essential Guidelines For Success.

#### Q: What are the benefits of using multilayer PCB design?

A: Multilayer PCB design offers several benefits over single-layer or double-layer designs. By using multiple layers, designers can achieve higher component density, reduce electromagnetic interference, and improve signal integrity. Multilayer PCBs also allow for more complex routing and shorter traces, leading to improved performance and reliability.

#### Q: What are some essential guidelines for successful multilayer PCB design?

A: .

1. **Layer stack-up**: Carefully choose the number and arrangement of layers in your PCB stack-up to optimize signal integrity, power distribution, and thermal management.

.

2. **Impedance control**: Maintain consistent trace widths and track impedances throughout the design to ensure signal integrity and minimize signal distortion.

.

3. **Ground and power planes**: Use solid ground and power planes to provide stable return paths for signals and reduce electromagnetic interference.

.

4. **Component placement**: Place components strategically to minimize signal crosstalk and interference, and optimize signal paths for improved performance.

Suggested reading:Electronic Components & Supplies

Who is the biggest PCB supplier?

Is PCB business profitable?

Your Guide to PCB Design Basics & Steps

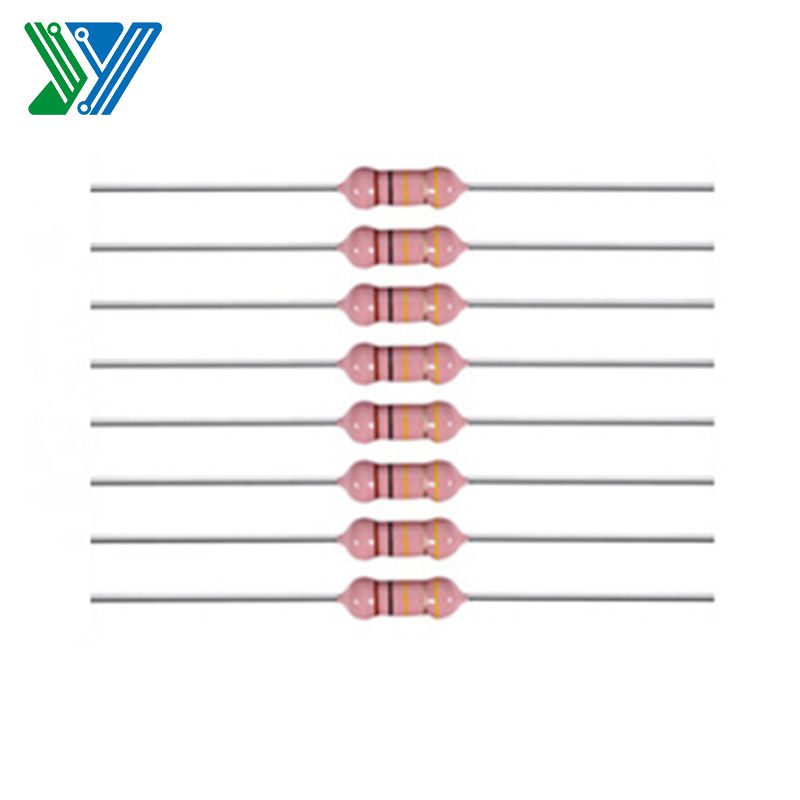

What are the benefits of thick film chip resistors?

Which features make a portable power station with an LFP battery an ideal choice for outdoor adventures?

Revolutionizing Connectivity with Communication Electronics PCBA

.

5. **Routing**: Plan your routing carefully to minimize signal loops, reduce EMI, and ensure signal integrity. Use differential pairs for high-speed signals.

.

6. **Decoupling capacitors**: Place decoupling capacitors strategically near power pins to suppress noise and provide stable power delivery.

.

7. **Thermal management**: Ensure adequate thermal vias and heat dissipation strategies to prevent overheating and ensure reliable operation.

.

8. **Design for manufacturability**: Consider manufacturing constraints and guidelines during the design process to avoid costly and time-consuming rework.

.

9. **Signal integrity analysis**: Perform signal integrity simulations and analysis to check for reflections, crosstalk, and other issues that could affect performance.

By following these guidelines and best practices, designers can optimize their multilayer PCB designs for maximum performance, reliability, and manufacturability.

For more information, please visit our website.

Are you interested in learning more about Industrial Control PCB Manufacturer? Contact us today to secure an expert consultation!

Additional reading:Encapsulated Transformer: Redefining Power Distribution for a Sustainable Future

A Comprehensive Comparison: LED Neon Flex vs. Traditional Neon Lights

How Do Deep Cycle Battery packs Work?

What are Types and Applications of Lithium Batteries?

What is OLED display module?

Exploring the Efficiency and Reliability of Eltek Rectifier Modules

LED Neon Flex vs. Traditional Neon Lights