How to Choose Infrared Windows? A Comprehensive Guide

You will get efficient and thoughtful service from CLZ.

Infrared windows are an essential component of any electrical maintenance program. They allow thermographers to safely and efficiently conduct inspections on energized electrical equipment without the need to open the panel doors. This not only saves time but also reduces the risk of arc flash incidents and other safety hazards. But with so many options available on the market, how do you choose the right infrared window for your needs? In this comprehensive guide, we will explore the key factors to consider when selecting an infrared window.

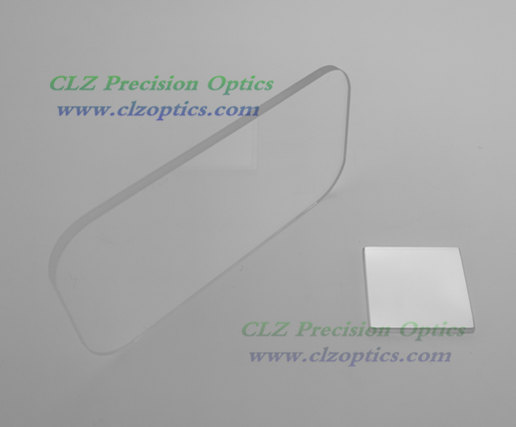

1. Material:

The first consideration when choosing an infrared window is the material it is made of. Infrared windows are typically made of either polymer or crystal materials. Polymer windows are light, durable, and cost-effective, making them a popular choice for most applications. Crystal windows, on the other hand, are more expensive but offer superior optical clarity and thermal stability. Consider the environment in which the window will be installed and choose a material that can withstand the conditions.

2. Size:

The size of the infrared window is another crucial factor to consider. The window should be large enough to allow for easy access to the equipment being inspected but not so large that it compromises the integrity of the panel. Measure the dimensions of the panel door and choose a window that fits snugly without obstructing the view of the components inside.

3. Field of view:

The field of view of the infrared window will determine how much of the electrical equipment can be inspected at once. A wider field of view is preferable as it allows for more efficient inspections and reduces the need to reposition the camera. Choose a window with a generous field of view to maximize your productivity.

4. Temperature rating:

Infrared windows are designed to withstand high temperatures generated by electrical equipment during operation. Check the temperature rating of the window to ensure it can handle the heat without compromising its integrity. A higher temperature rating is preferable for applications with extreme heat conditions.

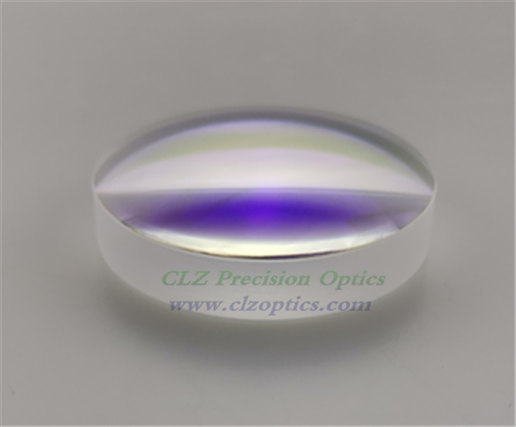

5. Optics:

Additional reading:10 Questions You Should Know about Application of Ultrasonic Testing

How to generate a single pulse?

4 Tips to Select an NDT UV LED Lamp Solution

Key Questions to Ask When Ordering Uv LED 6000+" - A Guide for Buyers

How to Choose In Ultrasonic Flaw Detection: A Comprehensive Guide

X-Ray Flaw Detector: A Comparison Guide

How to Choose the Best Eyeglass Lenses

The quality of the optics in an infrared window will have a significant impact on the clarity and accuracy of the thermal images captured during inspections. Look for windows with high-quality optics that minimize distortion and provide clear, sharp images. Anti-reflective coatings can also help improve image quality by reducing glare and reflections.

6. Certification:

Ensure that the infrared window you choose is certified to relevant industry standards, such as UL and IEC, to guarantee its safety and performance. Certified windows have undergone rigorous testing to ensure they meet quality and safety standards, giving you peace of mind during inspections.

7. Installation:

Proper installation of the infrared window is crucial to its effectiveness and safety. Follow the manufacturer's guidelines for installation to ensure the window is securely mounted and provides a clear view of the equipment. Consider factors such as accessibility, ease of maintenance, and sealing to prevent moisture ingress.

8. Maintenance:

Regular maintenance of the infrared window is essential to ensure its longevity and performance. Check the window for signs of wear and tear, such as cracks or discoloration, and replace it if necessary. Clean the window regularly to remove dirt, debris, and fingerprints that can affect image quality.

In conclusion, choosing the right infrared window is crucial for conducting safe and efficient electrical inspections. Consider factors such as material, size, field of view, temperature rating, optics, certification, installation, and maintenance to select a window that meets your specific needs. Investing in a high-quality infrared window will not only improve the accuracy of your inspections but also enhance safety and productivity. Choose wisely and protect your assets with the right infrared window.

Click here to get more.

If you want to learn more, please visit our website Infrared Windows.

Additional reading:Top Tips for Using a Sample Cutter

How X-Ray Flaw Detection System Works Efficiently

What Softness Testing Equipment for Sale Features?

Ultrasonic examination in Non-Destructive Examination (NDE)

Uncovering the Secrets of Pressure Decay Leak Testing

How to Choose the Right Makeup Mirror

How Does a Multi-Head Weigher Work?