Holographic Foil Paper: What Is It and How Do You Use It?

Holographic Foil Paper: What Is It and How Do You Use It?

Holographic foil paper is very intriguing and is even more interesting to use to your benefit. But you might wonder what it is and how to use it well.

Contact us to discuss your requirements of holographic printing paper. Our experienced sales team can help you identify the options that best suit your needs.

Paper is one of the most versatile materials out there. There’s almost no limit to the things manufacturers can do with paper. They can bend and design it to their benefit for whatever purpose they have. And with all the interesting creations out there, some might be less self-explanatory than others. We can help clear up confusion. Read on to learn about what holographic foil paper is and how you use it.

What Is Holographic Foil Paper?

If the name doesn’t intrigue you enough, the definition and purpose surely will. Holographic foil paper starts off as separate foil and paper components, which a manufacturer bonds in the printing process. Manufacturers perform the printing hot. The paper can be cardboard, cardstock, or another special material you have in mind. The foil adds value and movement to the paper giving it visual dimension. It has a two-dimensional design that produces a three-dimensional effect when the light hits it.

It’s similar to other metallic foils but includes an embossed pattern to showcase a spectrum of colors. The diffraction creates a rainbow effect that’s mesmerizing.

How Do You Use It?

The best way to use this material is for packaging decoration. There are other options, but this is ideal because it sells well and gives companies an identifying factor. It’s especially useful in the cosmetic field for labeling and paper conversion.

The paper is intriguing enough to draw the attention of customers while remaining relatively sleek. Businesses don’t want the decoration and packaging to distract from the products themselves. Catching a customer’s eye is enough to influence them to buy the items. Holographic foil paper is unique but doesn’t overpower branding.

Benefits of Holographic Foil Paper

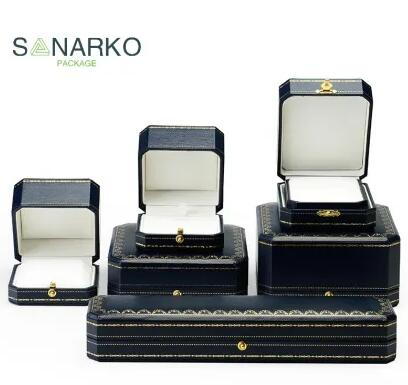

Aside from being eye-catching, holographic foil adds a sense of quality and exclusivity, which increases brand awareness. People will start associating your brand with this type of packaging and look for the products inside the store.

Using foil paper also improves the packaging quality and keeps the products inside fresh. You’ll see an increase in sales as a result. Don’t worry too much about expenses. This style of printing isn’t too high in price either.

Now that you know what holographic foil paper is and how to use it, start preparing to make it a part of your packaging process. Here at Announcement Converters Inc., you can get holographic foil paper. Shop with us today!

Holography-based 3D printing produces objects in ...

3D printers are useful devices for all kinds of reasons, but most have a critical weakness: they simply take a long time to actually make anything. That’s because additive manufacturing generally works by putting down an object one microscopic layer at a time. But a new holographic printing technique makes it possible to create the entire thing at once — in as little as a second or two.

For more information, please visit beer label paper.

Additional reading:11 Best Print-on-Demand Companies and Sites (2024)

What are the differences between pe bags, po bags and ...

How to Choose Bulk Buckets with Lids

Are 5L litre ice cream containers worth the hype?

How to Choose a Margarine Container

Euro Head Caps vs. Screw Caps: A Comparison

Why BOPP is the King of Film Label Materials

Light-based 3D printing techniques generally use lasers to cause a layer of resin to harden in a pattern, but like extrusion printers, they have to do it layer by layer. If the laser shined all the way through the liquid resin, it would cause a big line of it to cure.

But what if you shined multiple weaker lasers through the resin, none of which was powerful enough to cure it except when they all intersected? That’s the technique developed by a team led by researchers at Lawrence Livermore National Laboratory.

This basic idea has been applied in several other domains: by carefully overlapping weak beams of light, sound or radiation, you can expose a chosen volume to a critical amount while leaving other areas largely untouched.

In this case, the three beams of light must be carefully patterned to only intersect with each other and produce that constructive interference in the exact points that need to solidify. And once that pattern is set, it only takes a handful of seconds to actually complete the process of curing the resin — drain it away and your object is ready to use. A couple of other techniques have attempted something like this, but haven’t been able to create complete 3D shapes like this.

The advantages are plenty: you could, for instance, produce structures with other structures freely moving inside of them, like gears in a gearbox. There’s no need for support structures underneath overhangs, so certain shapes that were impractical or impossible when printing from the bottom up or top down are straightforward to create this way. You also could quickly print multiple structures simultaneously — a bunch of dice, for instance.

It’s still a bit crude compared with what comes out of most commercial 3D printers, but that’s to be expected — this is really just a proof of concept in a lab.

“With this work we’ve taken a solid first shot at this to demonstrate and prove out that ‘3D all at once’ fabrication is possible,” lead researcher Maxim Shusteff told TechCrunch in an email. “So we haven’t yet pushed the limits of any of the build performance metrics (speed, build size, resolution, complexity).”

Ultimately the “resolution” will likely be determined by the smallest bit of resin that can reliably be solidified, which has to do with a number of chemical and optical factors. It would be premature to speculate on what that resolution might be, but from the results already obtained it seems clear that it will certainly work for the complexity levels for which 3D printers are already being used.

Shusteff and his colleagues at LLNL, MIT, Berkeley and the University of Rochester aim to continue to develop this highly promising technique. Commercial applications are still a ways away, but it’s not hard to imagine parties that would be interested in a 3D printer that creates things in a few seconds rather than, at the very least, several minutes, and more often, hours.

Are you interested in learning more about yf packaging? Contact us today to secure an expert consultation!

Push Pull Caps for Sports and Fitness Enthusiasts

Exploring the Applications and Advantages of PE Aluminum Profile Protective Film

DTF Ink: Revolutionizing Textile Printing

Dry Sublimation Paper: A Comprehensive Guide to Printing on Various Surfaces

What products can be stored in child-resistant tins?

Understanding LPG Cylinder Installation and Maintenance: A Comprehensive Overview

The Difference Between Thermoforming and Cold Forming