Ceramic vs. Metallic Brake Pads, What's the Difference?

Ceramic vs. Metallic Brake Pads, What's the Difference?

Your braking system is perhaps the most critical safety mechanism in your vehicle. But while you rely on brakes every day to help you safely get from point A to B, you probably don't think about what's actually happening when you press on the brake pedal.

For more information, please visit brake pad for heavy duty.

Here's the basics of how the system works: when you step on your brake pedal, your car pushes pressurized fluid through its brake lines into a caliper at each wheel, where the brake pads are located. The brake fluid pushes the brake pads against a disc rotor in each wheel to slow it down, gradually bringing your wheels to a stop.

In other words, your brake system turns your car's kinetic energy into thermal energy through friction applied by the brake pads. In this article, we'll take a closer look at this critical component of your brake system and the pros and cons of each type ' ceramic vs. semi metallic brake pads, for instance ' to help you decide which is best for your vehicle and driving style.

A BRIEF HISTORY OF BRAKE PADS

These days, drivers typically have a choice between three types of brake pads: ceramic vs. semi metallic vs. organic brake pads. That wasn't always the case. The first use of brake pads goes all the way back to the 19th century. Bertha Benz ' famous inventor and wife of Mercedes-Benz founder Karl Benz ' is credited with creating the first brake pads out of leather for an early patent of their automobile in .

Since then, the materials used to make brake pads have evolved with advances in technology. It wasn't until the mid-to-late 20th century, as drum brakes were increasingly replaced by modern disc brakes, that manufacturers began producing the ceramic, metallic and organic brake pads used today.

ORGANIC BRAKE PADS

The brake pads in disc brakes were initially made from asbestos, a heat-absorbing material well-suited for the wear and tear that brake pads take on. However, asbestos was discovered to be a highly-potent carcinogen, causing cancer in those with prolonged exposure. When these asbestos-based brake pads had worn down, they would release asbestos into the air for drivers to unknowingly inhale. Manufacturers realized asbestos wasn't a safe compound to use in braking systems. As a result, organic brake pads ' or non-asbestos organic (NAO) brake pads ' were created to fill the gap.

Organic brake pads, which come standard on about 67% of new vehicles sold within the United States, are made of a mixture of fibers and materials such as rubber, carbon compounds, glass or fiberglass, and Kevlar', and are bound together with resin. They tend to produce less dust than some other types of brake pads, such as metallic pads, and are available at a lower price point.

Unlike performance brake pads, which are primarily used in heavy and high-performance vehicles, organic brake pads generate a moderate amount of friction without much heat being present, making them suitable for drivers who use their cars for everyday driving and commuting. Organic brake pads also tend to be quiet and don't put much stress on the brake rotors, which is a plus since brake rotors are often costly to repair or replace if damaged.

However, organic brake pads do have some disadvantages when compared to other types of brake pads. Organic brake pads can tend to wear out more quickly because of their composite nature, meaning they might have to be replaced more often. They also tend to function best within a smaller range of temperatures. They don't perform as well as semi metallic brake pads in extreme weather or when they are being pushed too hard and overheat. Organic brake pads also have a higher compressibility level, which means the driver has to press on the brake pedal with more force to engage them.

CERAMIC BRAKE PADS

Ceramic brake pads are made from material very similar to the type of ceramic used to make pottery and plates. Ceramic brake pad material, however, is denser and considerably more durable. Ceramic brake pads also have fine copper fibers embedded within them, to help increase their friction and heat conductivity.

Since they were developed in the mid-s, ceramic brake pads have consistently increased in popularity for a number reasons:

- Noise-Level: Ceramic brake pads are very quiet, creating little-to-no extra sound when the brakes are applied.

- Wear & Tear Residue: Compared to organic brake pads, ceramic brake pads tend to produce less dust and other particles as they wear down.

- Temperature & Driving Conditions: Compared to organic brake pads, ceramic brake pads can be more reliable in a broader range of temperatures and driving conditions.

Yet ceramic brake pads do have some limitations. Primarily, their cost: due to higher manufacturing costs, ceramic brake pads tend to be the most expensive of all brake pad types. Also, since both ceramic and copper can't absorb as much heat as other types of materials, more of the heat generated by braking will pass through the brake pads and into the rest of the braking system. This can cause more wear and tear on other braking components. Lastly, ceramic brake pads aren't considered the best choice for extreme driving conditions. If you're facing very cold weather or an upcoming race and you're choosing between ceramic vs. semi metallic brake pads, you'll want to go with metallic.

SEMI-METALLIC BRAKE PADS

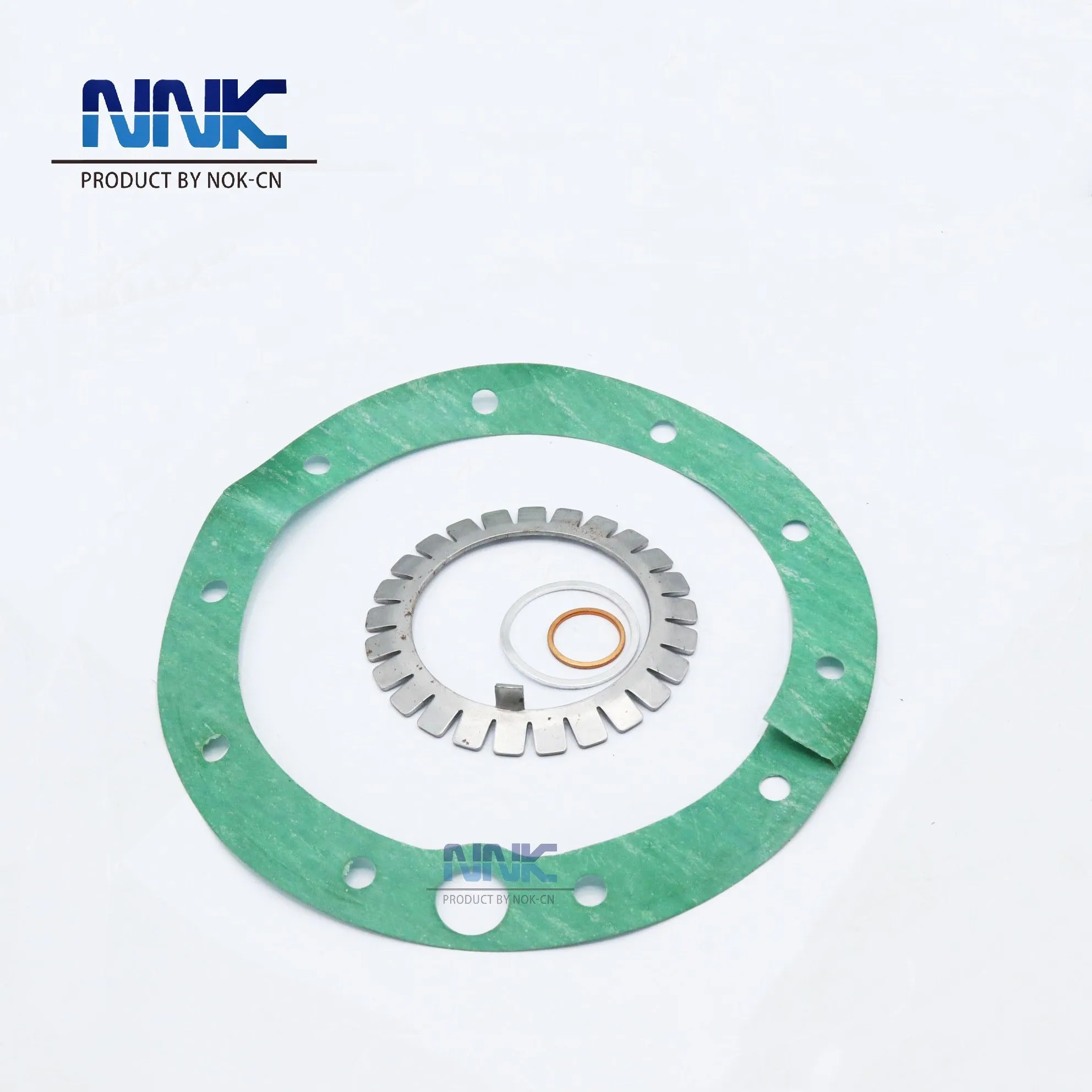

The final type of brake pad is the semi metallic brake pad. Semi metallic brake pads are different from fully metal brake pads in that they use fillers to create the pad compound instead of using 100% metal. Full metal brake pads are typically reserved for truly extreme braking requirements

Semi metallic brake pads are between 30% and 70% metal, including copper, iron, steel, and other composite alloys. These various metals are combined with graphite lubricant and other fillers to complete the brake pad. The metallic brake pad compounds available vary, each type offering their own advantages for everything from daily commutes to track racing.

For many drivers, especially those who value high-performance, the choice between ceramic vs. semi metallic brake pads is easy. Performance-driven drivers tend to prefer the metallic brake pads because they offer improved braking performance in a much more comprehensive range of temperatures and conditions. Because metal is such a good conductor of heat, metallic brake pads tend to withstand more heat while simultaneously helping braking systems cool back down more quickly. They also don't compress as much as organic brakes, meaning less pressure needs to be applied to the brake pedal to affect stopping ability.

However, there are some disadvantages when it comes to metallic vs. ceramic and organic brake pads. Metallic brake pads tend to be noisier than their ceramic or organic counterparts, leading to a louder ride. Metallic pads also put more stress on the brake system, adding more strain and wear on the brake rotors. As far as price goes, metallic brake pads tend to fall somewhere between organic and ceramic pads. They tend to produce more brake dust than the other two varieties as well.

CERAMIC VS. METALLIC VS. ORGANIC BRAKE PADS: WHICH IS RIGHT FOR YOU?

So which brake pad is the best choice for you between ceramic vs. semi metallic vs. organic brake pads? It depends on your vehicle manufacturer recommendations and the ride you expect from your vehicle combined with your driving style.

If you have a high-performance sports car, or at least drive your vehicle like one, you're likely better off choosing semi metallic brake pads. On the other hand, if you do a lot of urban commuting, you might find a solid ceramic brake pad to be the better option. If you don't put a lot of mileage on your vehicle, an organic brake pad might be the best, low-price option for your driving habits.

No matter which type you choose, have your brakes inspected and your brake pads replaced regularly. You'll know your brake pads need replacement when you hear the squeal of the metal 'tang' at the base of the pad as it comes into contact with the rotor. Tangs are built into all types of brake pads as an indicator of wear; if you hear it, don't wait too long to get new pads. At that point, deciding between ceramic vs. metallic brake pads ' or organic pads for a price-friendly option ' is up to you.

Below is a simple table that illustrates some of the comparative differences between organic, ceramic, and metallic brake pads.

BRAKE PAD TYPE

ORGANIC

CERAMIC

METALLIC

Price

$

$$$

$$

Performance

Low

Medium

High

Noise

Low

Very Low

High

Wear & Tear On Brake System

Low

Very Low

Medium

Best Brake Pads For Trucks in

4.8/5 - (116 votes)

Best Brake Pads For Trucks.

Brake pads create friction against disc brake rotors when you step on the brake pedal to slow or stop your truck. If you are looking for Best Brake Pads For Trucks in China. You are in the right place.

Since you will step on the brake pedal frequently, the brake pads will create wear and tear on rotors.

This means you may need to replace them after some time. Since brake pads vary in prices, durability, dust, and performance, you may need to check all available options before you settle for the best brake pad for your truck.

Types of brake pads for your truck

Brake pads manufacturers make four different brake pads for trucks.

These include semi-metallic brake pads, non-asbestos organic brake pads, low-metallic NAO brake pads, and ceramic brake pads.

The type of brake pad for your truck or SUV depends on your driving style, temperature conditions, performance, noise, and preference.

a. Semi-Metallic Brake Pads

Semi-metallic brake pads are the most common brake pads in the market.

Additional reading:Are semi metallic brakes shoes good?

The Role of Heavy-Duty Tension Springs in Machinery Applications

Fancy Tanzanite - Rare Green, Yellow, Orange and Pink ...

Is it ok to paint coil shock springs? - Pinkbike Forum

CAR-GRAND Chameleon Iridescent Reflective PU ...

A scooter company is… profitable?

What is so good about Polestar?

Are you interested in learning more about brake pad manufacturer? Contact us today to secure an expert consultation!

They are made using semi-metallic components like steel wool, wire, and copper.

These elements are bound together using organic resin and molded into shapes.

The structure is then baked in a furnace to harden.

Semi-metallic brake pads are robust, heat resistant, and easier on brake rotors.

Accordingly, they tend to be less expensive compared to ceramic brake pads.

One of these brake pads' most notable performance features is their heavy braking, making them ideal for heavy vehicles and high-performance cars.

One drawback of semi-metallic brake pads is that they perform poorly in low temperatures.

b. Ceramic Brake Pads

Ceramic brake pads are the latest designs in the world of brake pads.

They make excellent braking and have better heat absorption for instant and quick stops.

Ceramic brake pads are made from ceramic fiber bound with filler materials.

These brake pads are quieter and cleaner as they produce finer dust that does not stick to wheels.

Accordingly, they are durable than organic brake pads.

A significant drawback of ceramic brake pads is their hefty price tags.

Additionally, they may not be ideal for heavy vehicles.

c. Low-Metallic NAO Brake Pads

Low-Metallic NAO brake pads offer a better braking option.

These brake pads are made from organic formula combined with copper or steel.

These compounds help in heat transfer, making them ideal for performance trucks.

On the downside, low-metallic NAO brake pads are noisy, while the metallic addition produces a lot of dust.

d. Non-Asbestos Organic Brake Pads

NAO brake pads are made from organic components.

However, there was a time when they were constructed from asbestos.

The asbestos material was replaced due to health and safety concerns.

Currently, they are manufactured using glass fiber, rubber, or Kevlar bound together with resins.

NAO brake pads are softer and relatively quieter.

Accordingly, they are easier on brake rotors or discs.

However, they tend to wear and tear faster than any other brake pad.

Therefore, non-asbestos organic brake pads are not ideal for performance cars, heavy cars, or frequent braking needs.

Video Link:

Finding the Best Brake Pads for Trucks

Brake pads often wear and tear after some time.

The average brake pads need replacement after 30,000 to 70,000 miles.

However, the duration may vary, depending on your driving style, weather conditions, and type of brake pads on your truck.

When it comes to choosing the best brake pads for trucks, you should consider the following:

- Cost

- Performance

- Noise

- Tear and wear

- Model and compatibility

The best brake pads for trucks

Here are the five best brake pads for trucks:

1.Power Stop K Front Z23 Evolution Brake Kit

This Power Stop brake pad kit comes with better braking performance suitable for heavy-duty truck applications.

The Power Stop K Front Z23 Evolution Brake kit also features quiet and low-dust brake pads for better overall performance.

More interesting about this set is that it contains all components you need to install the brake pads, including discs.

This brake pad will enhance your truck's style and offer the best braking performance in various weather conditions.

2.StopTech 309. Metallic Brake Pads

These StopTech brake pads offer unparalleled performance in the market.

They are a perfect choice if you want your truck to slow down quickly.

Accordingly, they are ideal for heavier vehicles such as SUVs and trucks.

However, the StopTech 309. Metallic Brake Pads produce a lot of dust and may not be ideal if you want cleaner wheels.

3. Power Stop Extreme Truck & Tow Disc Brake Pads

The Power Stop Extreme Truck and Tow Disc Brake Pads are aggressive and durable brake pads for trucks and SUVs.

These brake pads are custom-designed to fit any truck model, and they also offer excellent braking performance over a wide range of temperatures and tracks.

4. Bosch BC914 QuietCast Premium Ceramic Brake Pads

The Bosch BC914 QuietCast Premium Ceramic Brake Pads are easily among the best brake pads for trucks.

These brake pads have the perfect balance of stopping power and noise reduction.

Accordingly, the Bosch BC914 QuietCast Premium Ceramic Brake Pads are highly responsive, allowing your truck to slow or stop without applying too much pressure on the brake pedal.

Their noise-reducing feature will ensure a quieter, smoother drive for longer.

Lastly, the Bosch BC914 QuietCast Premium Ceramic Brake Pads do not contain copper and come with everything you need to install them.

5. Akebono ACT537 ProAct Ultra-Premium Ceramic Brake Pads

The Akebono ACT537 ProAct Ultra-Premium Ceramic Brake Pads are among the best aftermarket brake pads.

These brake pads are highly durable, offering more mileage than most brake pad brands in the market.

Accordingly, they come with similar features and specifications as OEM brake pads, making them compatible with many car models.

The Akebono ACT537 ProAct Ultra-Premium Ceramic Brake Pads offer superior braking performance in heavy vehicles such as trucks and SUVs with better-stopping power at an affordable price.

The bottom line

Trucks are generally heavy vehicles, and their applications involve more weight, putting more pressure on brake pads.

Therefore, you need to be sure that you get the best brake pads for trucks.

Consider inspecting your braking system frequently for any wear.

If you hear squealing sounds, it might be time to replace the brake pads in your trucks.

This article has listed some of the best brake pads for trucks, giving you ample time to select what you want.

If you want to learn more, please visit our website passenger car brake pad.

10 Questions You Should Know about White BYD Seagull 2026

Aventon's Guide On How to Choose An Electric Bike

When to Use 8.5 inch solid scooter tyres?

Commercial Vehicle Brake Pad Replacement: Step-by-Step Guide

Best Brake Pads for 2023: A Comprehensive Guide

Why Are Electric Motorcycles So Popular?

Introducing MG Auto Parts: Unleash Your Car's Full Potential