Advantages and Applications of Seamless Steel Cylinder

Seamless steel cylinders are a remarkable feat of engineering, designed to safely store and transport various gases under high pressure. These cylinders are widely used in industries, healthcare, laboratories, and even in our daily lives. In this comprehensive article, we will explore the advantages of seamless steel cylinders, their diverse applications, and the safety measures in place to ensure their reliable usage.

Advantages of Seamless Steel Cylinders

High Strength

Seamless steel cylinders boast exceptional strength due to their seamless construction, making them capable of withstanding high internal pressure without deformation or leakage.

Safety Assurance

The seamless design eliminates the risk of weak points or potential leaks, ensuring the utmost safety during gas storage and transportation.

Durability

Constructed from high-quality steel, these cylinders exhibit impressive durability and have a longer service life compared to cylinders with welded seams.

Corrosion Resistance

Seamless steel cylinders are coated with corrosion-resistant materials, protecting them from external elements and extending their lifespan.

Lightweight

Despite their robustness, seamless steel cylinders are surprisingly lightweight, making them more manageable and easier to handle during usage and transportation.

Applications of Seamless Steel Cylinders

Seamless steel cylinders applications across various industries and daily activities:

1. Medical and Healthcare

In the medical field, seamless steel cylinders are commonly used to store medical gases like oxygen, nitrous oxide, and medical air. These cylinders provide a reliable source of gases for patients in hospitals, clinics, and emergency situations.

2. Industrial Gases

Industries rely on seamless steel cylinders to store and transport industrial gases such as hydrogen, nitrogen, argon, and acetylene. These gases play crucial roles in manufacturing processes, welding, cutting, and chemical synthesis.

3. Scuba Diving

Seamless steel cylinders serve as essential diving tanks for scuba divers, providing a steady supply of compressed air or other breathing gases during underwater explorations.

Suggested reading:Packaging & Printing

4. Fire Extinguishers

Aluminium Flip Off Seal: Ensuring Product Integrity and Security

Choosing the Right Handheld Inkjet Printer: Features and Considerations

Why Is Pizza Round But The Box Is Square?

Ideas for Incorporating Shrink Film into Creative Promotional Packaging Designs

Choosing the Right LPG Gas Cylinder: Size, Capacity, and Usage Considerations

Where Can I Find Custom Jewelry Packaging Suppliers?

Certain types of fire extinguishers use seamless steel cylinders to house extinguishing agents like carbon dioxide (CO2) or dry chemical powder.

5. Beverage Dispensing

In the beverage industry, seamless steel cylinders are utilized to store and dispense carbon dioxide (CO2) for carbonating beverages like soda and beer.

Safety Measures for Seamless Steel Cylinders

While seamless steel cylinders offer numerous advantages, ensuring their safe handling and usage is of utmost importance. Here are essential safety measures:

Regular Inspections

Cylinders should undergo regular inspections to identify signs of wear, corrosion, or damage. Certified professionals should conduct these inspections, and any defective cylinders should be taken out of service.

Proper Storage

Store seamless steel cylinders in a cool, dry, and well-ventilated area, away from direct sunlight, heat sources, or flammable materials.

Handling Precautions

When handling cylinders, ensure they are upright and properly secured to prevent falls or damage. Avoid dropping or rolling cylinders, as this can cause severe accidents.

Transportation Safety

During transportation, secure cylinders in an upright position and avoid stacking them. Properly label the cylinders to indicate their contents.

Valve Protection

Protect cylinder valves with fitted valve caps to prevent damage and to keep out dirt and debris.

Conclusion

Seamless steel cylinders are an indispensable part of various industries, providing a safe and efficient means of storing and transporting gases under pressure. Their high strength, durability, and safety features make them ideal for diverse applications, ranging from medical and industrial use to scuba diving and beverage dispensing.

To ensure seamless steel cylinders' continued safe usage, regular inspections, proper handling, and adherence to safety guidelines are essential. By following these precautions, users can fully harness the advantages of seamless steel cylinders and optimize their performance in a multitude of scenarios.

Additional reading:Benefits of UV Curable Ink in Screen and Digital Printing

What are the Uses of Sticky Sublimation Paper?

Non-Wet Strength Metallized Paper: Revolutionizing Packaging Solutions

Choosing the Perfect Industrial Barcode Printer for Your Business

How to Choose the Right CNG Cylinder: A Comprehensive Guide

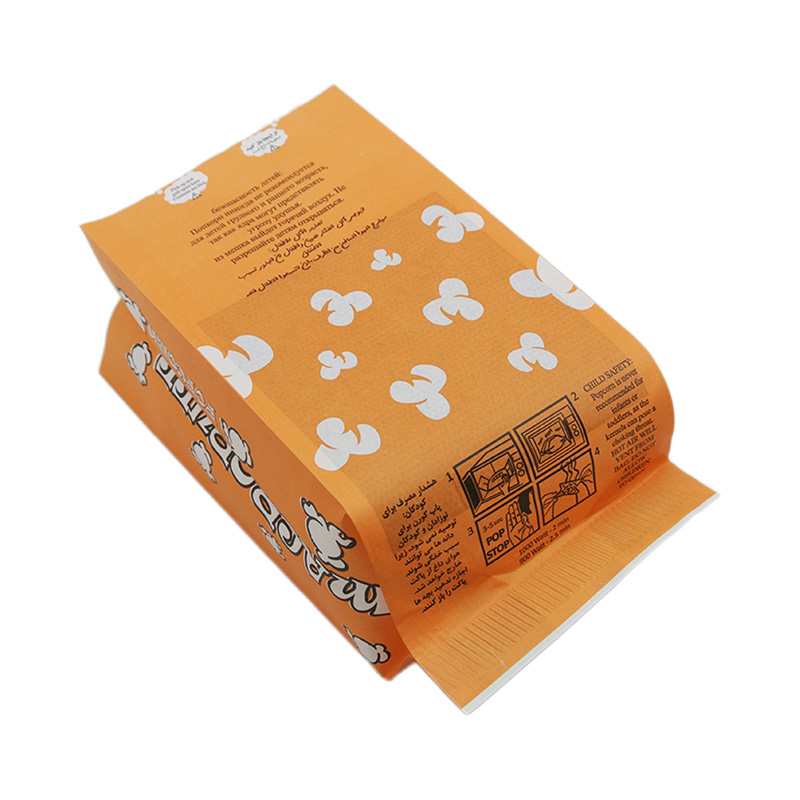

The Science and Art of Microwave Popcorn Bags: Popping Perfection at Your Fingertips

Things To Consider When Choosing Frozen Food Pouches